MIL-DTL-5675C

4.8.2 Inspection lot.

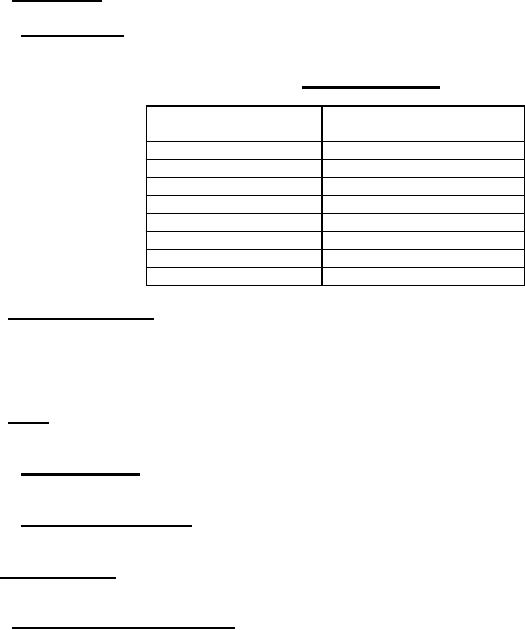

4.8.2.1 Lot and sample. The inspection lot shall be product selected at random from the production lot

without regard to quality and shall be the sample size specified in table V.

TABLE V. Lot and sample size.

Production

Sample size

lot size

1 to 90

8

91 to 150

12

151 to 280

19

281 to 500

21

501 to 1200

27

1201 to 3200

35

3201 to 10,000

38

10,001 to 35,000

46

4.8.3 Bend and tension test. The shackles being tested shall be opened by means of a wedge under

gradual pressure, or otherwise, until the minimum opening is at least equal to the specified inside

diameter of the shackle, without cracking. The shackle shall then be returned to its original shape end the

required load shall be applied through a shackle or a U-bolt similar in shape and size to the thimble-

normally used with the shackle under test.

4.8.4 Finish. The surface condition of the entire sample shall be examined under a five-time magnification

for imperfections as listed in 3.6

4.8.4.1 Grade A shackles. Plating thickness shall be tested in accordance with the applicable plating

specification, ASTM E376

4.8.4.2 Grades B and C shackles. Grades B and C shackles shall be tested for corrosion resistance for a

period of 200 hours in accordance with ASTM B117.

4.9 Salt spray testing. Fittings when subjected to corrosion resistance testing in accordance with ASTM

B633 and ASTM B117, shall meet the requirements of 3.6.1. The following details shall apply:

4.9.1 Visual and mechanical inspection. Shackles shall be examined to ensure conformance with this

specification and associated specification sheets. Continuous examination shall be performed to assure

compliance with the following requirements:

a.

First article (see 3.1).

b.

Design, construction and physical dimensions (see 3.4).

c.

Workmanship (see 3.7).

d.

5. PACKAGING

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business