MIL-DTL-23599B(AS)

4.5 Inspection methods.

4.5.1 Visual examination. Each rescue hook selected in accordance with table I shall be

examined visually to determine conformance with this specification. Table II shall be used to

classify the defects found.

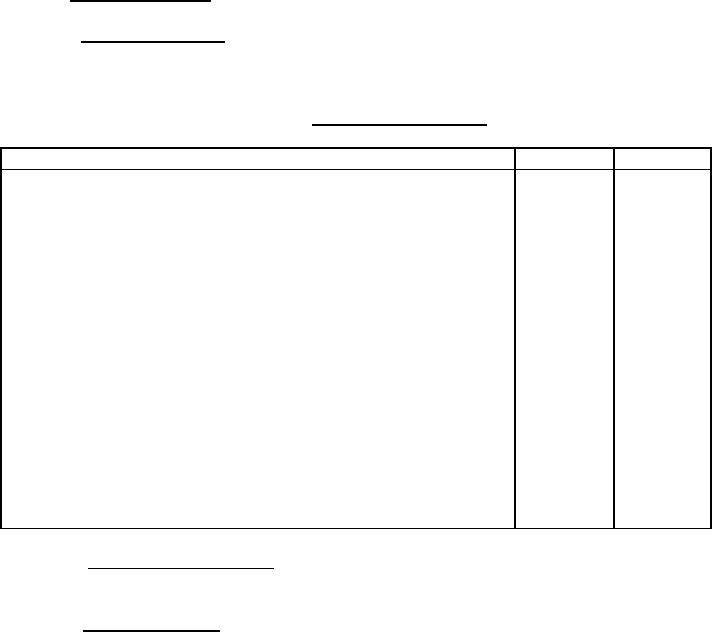

TABLE II. Classification of defects.

DEFECT

CRITICAL

MINOR

X

Material imperfections-foreign matter embedded

X

Surface-unclean, rough, misaligned or containing cracks,

nicks or other flaws

X

Any component missing, fractured, malformed, or otherwise

damaged

X

Any component loose or otherwise not securely retained

X

Incorrect assembly or improper positioning of components

X

Any functioning part that works with difficulty

X

Faulty workmanship that would materially reduce performance,

reliability, or durability

X

Faulty workmanship or defects that would not materially reduce

performance , reliability, or durability

Measurement deviating from the dimensions and tolerances

X

4.5.2 Dimensional examination. Each rescue hook selected as a sample unit shall be

thoroughly checked dimensionally to determine conformance to this specification.

4.5.3 Metal examination. The rescue hooks shall be examined to ensure that they are

free from all sharp edges, burrs, cracks or any other imperfections which could affect the

performance of the hooks. Each hook shall pass the following inspection criteria:

a. Chemical certification in accordance with SAE-AMS 5643 for forged hooks and

SAE-AMS 5355 for cast hooks.

b. Physical certification in accordance with SAE-AMS 5643 for forged hooks and

SAE-AMS 5355 for cast hooks.

c. Solution heat treat in accordance with SAE-AMS 5463 for forged hooks and

homogenization and solution heat treat in accordance with SAE-AMS 5355 for cast hooks.

d. Passivation in accordance with SAE-AMS 2700, type 2.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business