FF-C-450F

employed for saddles meets the requirements of 3.1.2. In lieu of such report, the contractor shall carry out necessary

tests of the iron under Government surveillance to show conformance with 3.1.2.

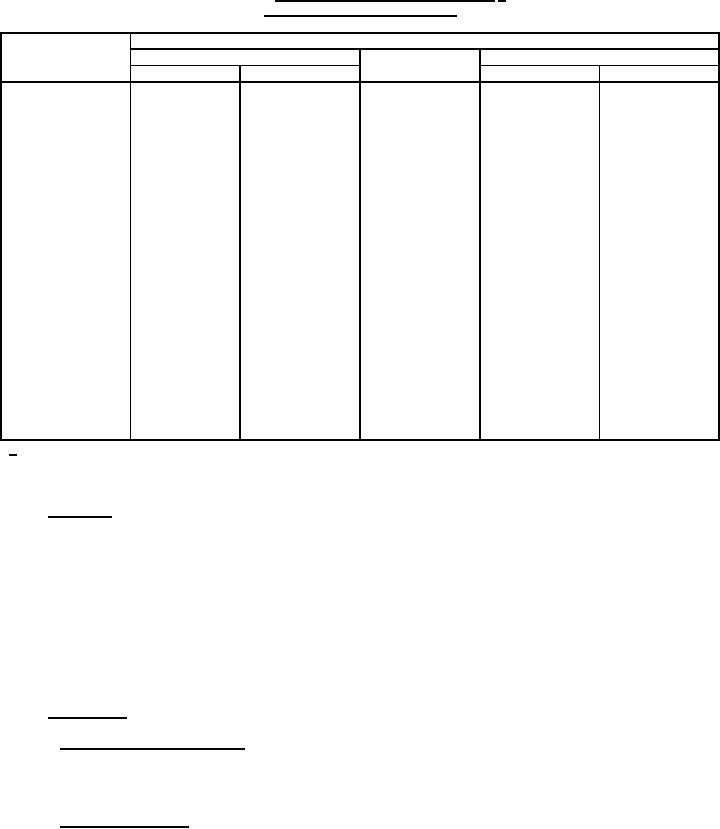

TABLE II. Torque values for torque testing only 1/

(Applies to wire rope clamp nuts).

Nominal

Nut torque

clamp size

Type I

Type II

Type III

wire rope

Class 1

Class 2

Class 1

Class 2

1/8

(.125)

34 in-lbs

34 in-lbs

34 in-lbs

3/16

(.188)

66 in-lbs

32 in-lbs

78 in-lbs

78 in-lbs

14 ft-lbs

¼

(.250)

12 ft-lbs

12 ft-lbs

144 in-lbs

144 in-lbs

24 ft-lbs

5/16

(.313)

18.5 ft-lbs

12 ft-lbs

222 in-lbs

222 in-lbs

40 ft-lbs

3/8

(.375)

25 ft-lbs

18.5 ft-lbs

25 ft-lbs

25 ft-lbs

66 ft-lbs

7/16

(.438)

35 ft-lbs

18.5 ft-lbs

35 ft-lbs

35 ft-lbs

100 ft-lbs

1/2

(.500)

35 ft-lbs

25 ft-lbs

43 ft-lbs

43 ft-lbs

100 ft-lbs

9/16

(.563)

50 ft-lbs

35 ft-lbs

50 ft-lbs

50 ft-lbs

146 ft-lbs

5/8

(.625)

50 ft-lbs

35 ft-lbs

75 ft-lbs

75 ft-lbs

146 ft-lbs

3/4

(.750)

100 ft-lbs

50 ft-lbs

100 ft-lbs

100 ft-lbs

200 ft-lbs

7/8

(.875)

140 ft-lbs

100 ft-lbs

140 ft-lbs

140 ft-lbs

335 ft-lbs

1

(1.000)

140 ft-lbs

100 ft-lbs

190 ft-lbs

190 ft-lbs

335 ft-lbs

1-1/8

(1.125)

140 ft-lbs

140 ft-lbs

220 ft-lbs

220 ft-lbs

335 ft-lbs

1-1/4

(1.250)

275 ft-lbs

140 ft-lbs

275 ft-lbs

275 ft-lbs

500 ft-lbs

1-3/8

(1.375)

275 ft-lbs

275 ft-lbs

340 ft-lbs

340 ft-lbs

500 ft-lbs

1-1/2

(1.500)

275 ft-lbs

275 ft-lbs

420 ft-lbs

420 ft-lbs

775 ft-lbs

1-5/8

(1.625)

420 ft-lbs

480 ft-lbs

480 ft-lbs

1-3/4

(1.750)

590 ft-lbs

590 ft-lbs

590 ft-lbs

2

(2.000)

750 ft-lbs

750 ft-lbs

750 ft-lbs

2-1/4

(2.250)

750 ft-lbs

820 ft-lbs

820 ft-lbs

2-1/2

(2.500)

750 ft-lbs

1150 ft-lbs

1150 ft-lbs

2-3/4

(2.750)

750 ft-lbs

1450 ft-lbs

1450 ft-lbs

3

(3.000)

1200 ft-lbs

1650 ft-lbs

1650 ft-lbs

1/ Not to be used for application nut torque values.

5. PACKAGING

5.1 Packaging. For acquisition purposes, the packaging requirements shall be as specified in the contract or order

(see 6.2). When packaging of materiel is to be performed by DoD or in-house contractor personnel, these personnel

need to contact the responsible packaging activity to ascertain packaging requirements. Packaging requirements are

maintained by the Inventory Control Point's packaging activities within the Military Service or Defense Agency, or

within the military service's system commands. Packaging data retrieval is available from the managing Military

Department's or Defense Agency's automated packaging files, CD-ROM products, or by contacting the responsible

packaging activity.

6. NOTES

INFORMATION FOR GUIDANCE ONLY. This section contains information of a general or explanatory nature that is

helpful, but is not mandatory.

6.1 Intended use.

6.1.1 Type I, II and III clamps, bolted. Types I, II and III wire rope clamps are intended for use on wire rope eye-

loop connections or complete-loop, end-to-end connections where socketing or splicing is not feasible when a

nonpermanent or temporary joint is required. The clamps also may be used in an end-to-end connection to make a

continuous length wire rope, but in emergency cases only.

6.1.2 Single-saddle clamps. Single-saddle wire rope clamps, type I, may be used interchangeably with double-

saddle wire rope clamps, type II and type III, class 1, on wire ropes of the same diameter but should not be used

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business