FF-C-450F

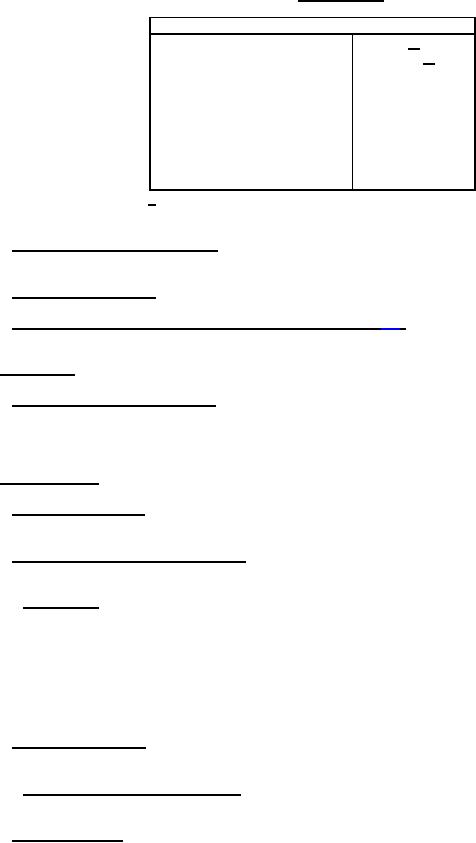

TABLE I. Sampling plan.

Lot Size

Sample size

2

to

8

1/

9

to

15

13 1/

16

to

25

13

26

to

50

13

51

to

90

13

91

to

150

13

151

to

280

20

281

to

500

29

501

to

1,200

34

1,201

to

3,200

42

1/ Indicates entire lot must be inspected or sample size not to exceed lot size.

4.2.3 Sampling for protective finish tests. Sampling for tests of protective finishes shall be in accordance with the

applicable specifications of 3.5.4.

4.2.4 Sampling for torque test. A random sample of types I, II and III clamps, as applicable, see 4.2.2.

4.2.5 Sampling of type IV nuts for magnetic particle inspection (see 6.2). When magnetic particle inspection is

specified in the contract or order, a random sample of type IV nuts shall be taken from each lot see 4.2.2.

4.3 Examination.

4.3.1 Visual and dimensional inspection. Each clamp taken as specified in 4.2.2 shall be examined to verify

compliance with this specification. Examination shall be conducted in accordance with table I. Any clamp in the

sample containing one or more defects shall be rejected and if the number of defective clamps exceeds the

acceptable number for the sample, the lot represented by the sample shall be rejected.

4.4 Test procedures.

4.4.1 Protective coating test. Test of protective coating shall be conducted in accordance with the applicable

specifications of 3.5.4.

4.4.2 Torque test of types I, II, and III clamps. Unless otherwise stated in contract or order, each sample of 4.2.5

4.4.2.1 Test method. Two steel rods, of the same diameter as the wire rope for which the clamp is intended, shall

be inserted in the clamp opening (see figure 1). The clamp nuts shall be tightened with a torque wrench to the

applicable torque values specified in table II. Tightening shall be accomplished progressively by applying torque

alternately to each nut in increments of ten percent of the maximum torque values for the size clamp being tested.

The maximum torque on each nut shall be held for ten minutes. After the ten minute period, clamps shall be

disassembled and visually examined for distortion, then tested by being reassembled and disassembled by hand

without tools. Clamps unable to perform this test shall be considered defective. This torque test does not apply to

type IV clamps.

4.4.3 Test of type IV clamps. The contractor shall furnish an Underwriter's Laboratories, Inc. approved test report.

When this listing is not available, the contractor shall submit proof that the clamp grip conforms to 3.6.2.

4.4.3.1 Magnetic particle test of type IV nuts. When specified in the contract or order, type IV nuts shall be

examined and tested in accordance with ASTM-E1444 (see 6.2).

4.4.4 Malleable-iron test. When malleable-iron saddles (type I, class 2 clamps) are specified, the contractor shall

furnish, prior to production, a test report by a laboratory acceptable to the Government that the malleable-iron

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business