AN116 Rev 3

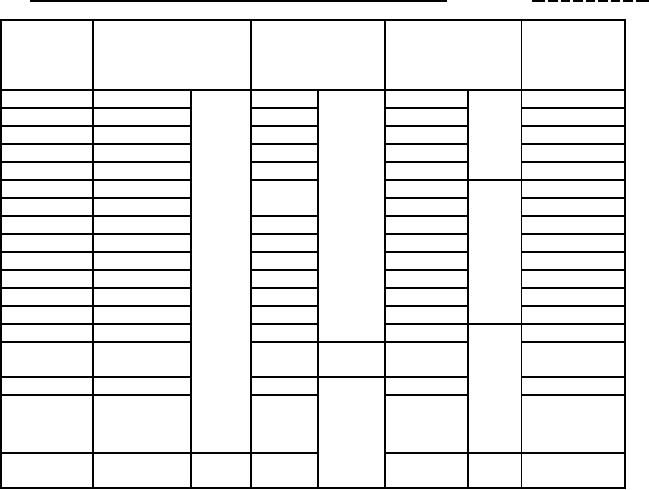

Table I. Dimensions for shackle, anchor, forger carbon steel screw PIN. continued. 1/2/3/4/5/6/7/8/9/

AN Part

R

Thread T

W

WT, LB

or Identifying

Outside dia. eye (mm)

MIL-S-7742

Width between

Approx.

Number

eyes, (mm)

(gm.)

(PIN)

AN116-3

.594(15.09)

1/4-20

.375(9.5)

.08(30)

AN116-4

.719(18.26)

5/16-18

.469(12)

.12(45)

± .031

AN116-5

.875(22.23)

3/8-16

.531(13.5)

.21(78)

(.079)

AN116-6

1.000(25.4)

7/16-14

.656(16.7)

.32(119)

AN116-7

1.125(28.58)

1/2-13

.719(18.3)

.49(183)

UNC-2A .812(20.6)

AN116-8

1.312(33.32)

5/8-11

.73(272)

UNC-2B .875(22.2)

AN116-9

1.438(36.53)

.92(343)

1.625(41.28) ± .062

AN116-10

3/4-10

1.062(27)

1.51(564)

1.875(47.63) (1.6)

AN116-12

7/8-9

1.250(32.)

2.26(844)

± .062 3.40(1269)

AN116-14

2.062(52.37)

1-8

1.438(37)

(1.6)

AN116-16

2.438(61.93)

1-1/8-7

1.688(43)

4.95(1848)

AN116-18

2.688(68.28)

1-1/4-7

1.812(46)

6.91(2579)

AN116-20

3.000(76.2)

1-3/8-6

2.000(51)

8.99(3355)

AN116-22

3.312(84.12)

1-1/2-6

2.250(57)

12.19(4550)

AN116-24

3.562(90.47)

1-5/8 -

NS-2A

2.375(60)

15.95(5953)

± .125

5-1/2

NS-2B

(3.2)

AN116-26 3.812(96.82)

1-3/4 - 5

2.625(67)

19.10(7129)

UNC-2A 2.875(73)

AN116-28 4.062(103.17)

2-41/2

27.50(10264)

UNC-2B

AN116-32 4.625(117.48) ± .125

2-1/4 -

3.250(83)

39.00(14556)

(3.2)

4-1/2

See notes at end of table.

NOTES:

1. Dimensions are in inches.

2. Metric equivalents are given for information only.

3. Break sharp edges .and remove all hanging burrs and slivers.

4. Unless otherwise noted tolerances shall be ±.005 inches (0.13 mm) and angles ±.5°.

5. Machined surfaces shall be smooth to 125μin Ra, hex surfaces may be 250μin Ra, unless otherwise

specified on the figures. Surface finish shall be in accordance with ASME B46.1.

6. Type: RR-C-271, type IVA, class 2, with the exception of the requirements of this specification.

7. Maximum working load equal to 1/5 minimum breaking strength as specified in table I.

8. Material: Forged carbon steel, see procurement specification RR-C-271.

9. Finish: Zinc coating, see procurement specification, except if the hot-dip (galvanizing) process is used,

the coating shall be applied in accordance with specification ASTM A153/A153M.

4